Description

Freeze Dried Ice Cream is an Australian made equivalent of the famous ‘Astronaut Ice Cream’. Available in packs of 50 or packs of 10.

Supplied in a zip seal stand-up pouch. Sits easily on the shelf. We use ice cream slices and freeze dry them in Tasmania. Product shelf life 2 years from manufacture.

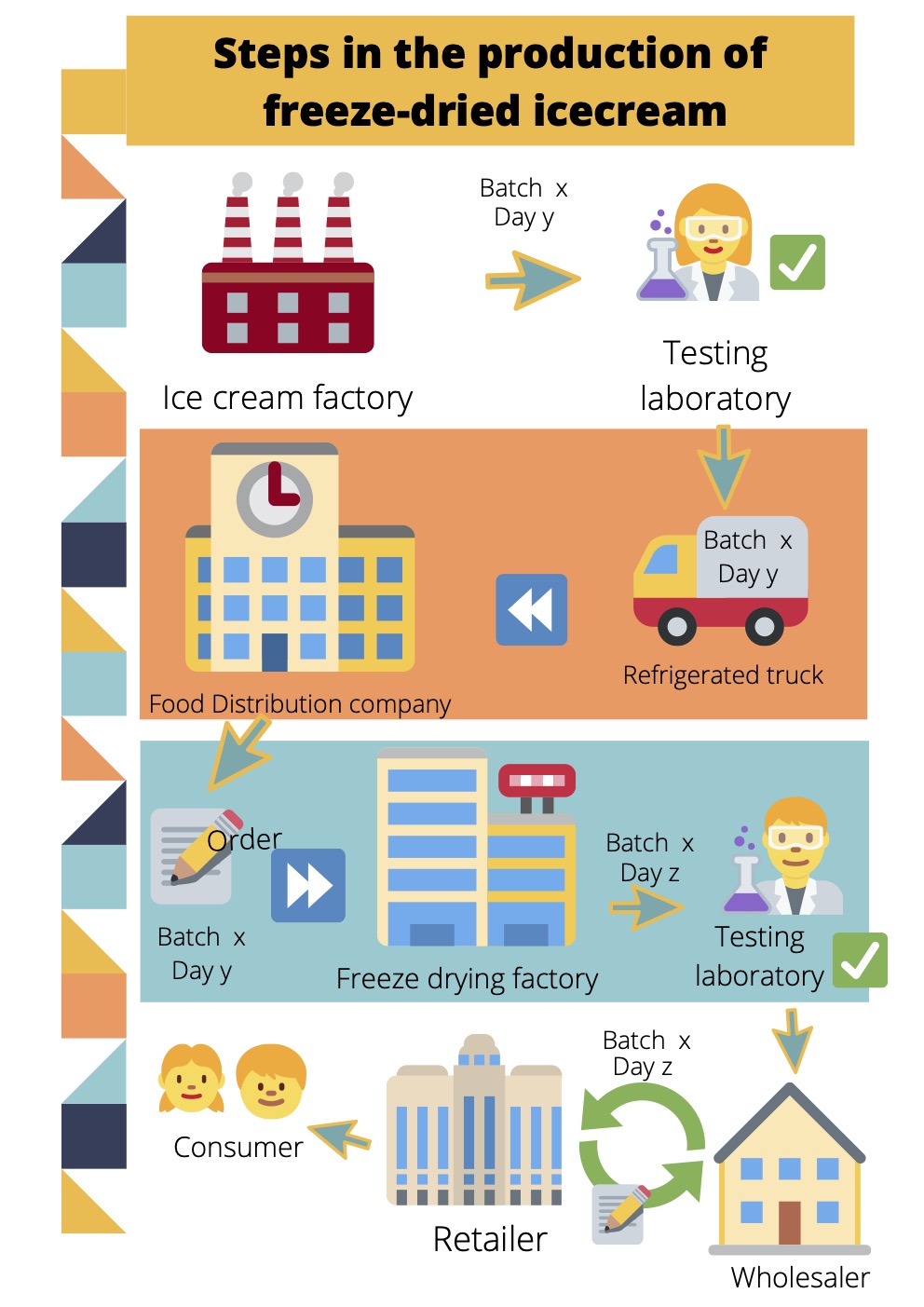

The process of freeze drying involves extracting most of the moisture leaving behind a drier, slightly crumbly product which retains all the flavour of vanilla ice ream. (see images attached for more information.

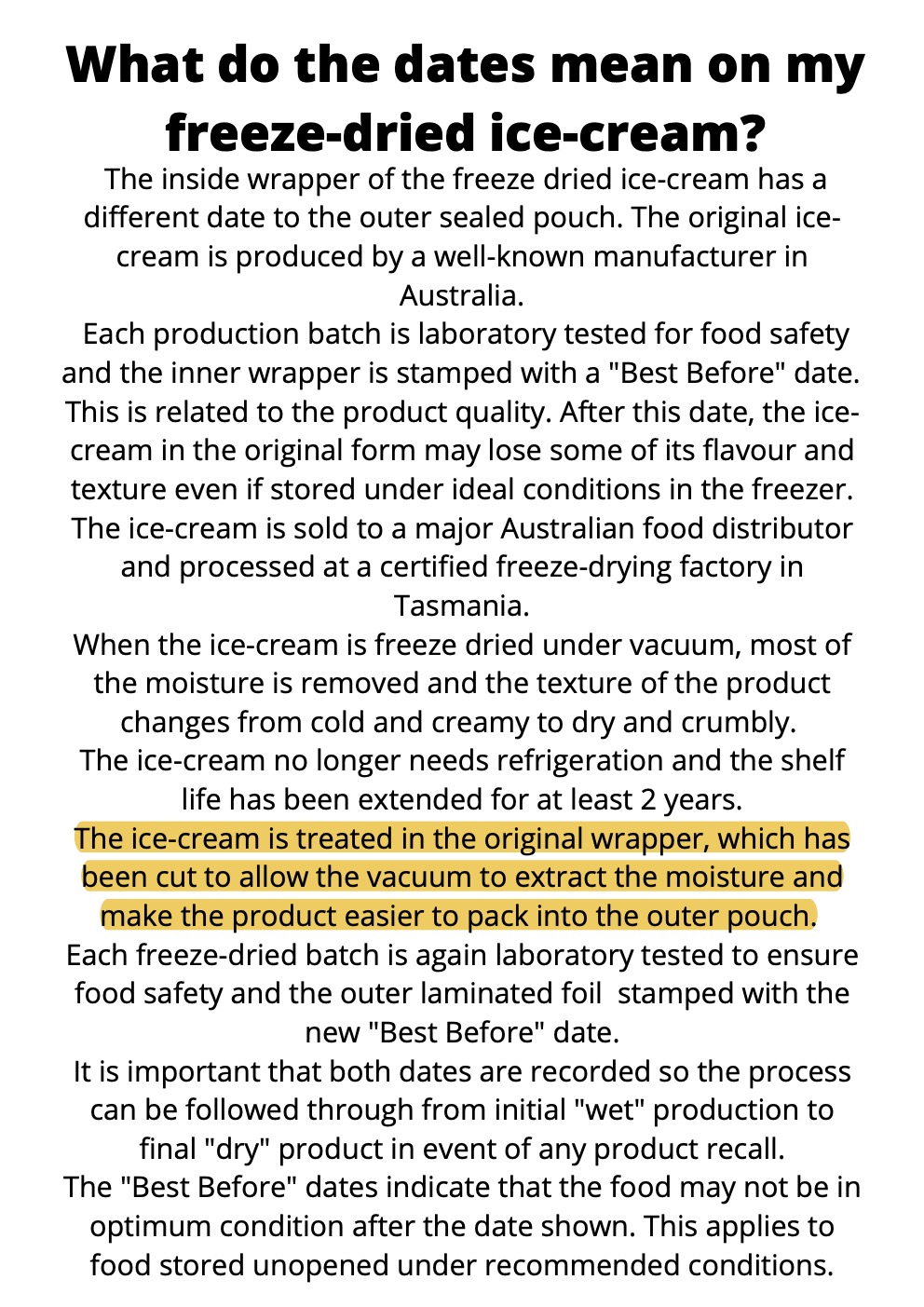

See the back panel for important information, printed in yellow. It provides information about the production process.

Use this versatile product as a snack whilst enjoying the outdoors, or as an ingredient in delicious foods.

Try our Freeze Dried Dinosaur Poo.

🧊 How Freeze Drying Works: A Step-by-Step Overview

1. Freezing

The process begins by freezing the ice cream solid at very low temperatures, typically around −40 °C (−40 °F) or even colder. This step ensures that all water in the ice cream is in the form of ice.

2. Vacuum Chamber (Primary Drying / Sublimation)

The frozen ice cream is placed in a vacuum chamber. Under low pressure, the temperature is slowly raised, but not enough to melt the ice. This causes sublimation, where ice transforms directly from a solid to a vapor, bypassing the liquid phase entirely.

-

Why sublimation? Sublimation allows the water to leave the food without disrupting its physical structure, preserving the shape, volume, and even air pockets in the ice cream.

3. Secondary Drying (Desorption)

After most of the ice has sublimated, the temperature is increased further to remove any remaining bound water molecules. This phase is essential to bring the moisture content down to about 1–4%, ensuring long-term shelf stability.